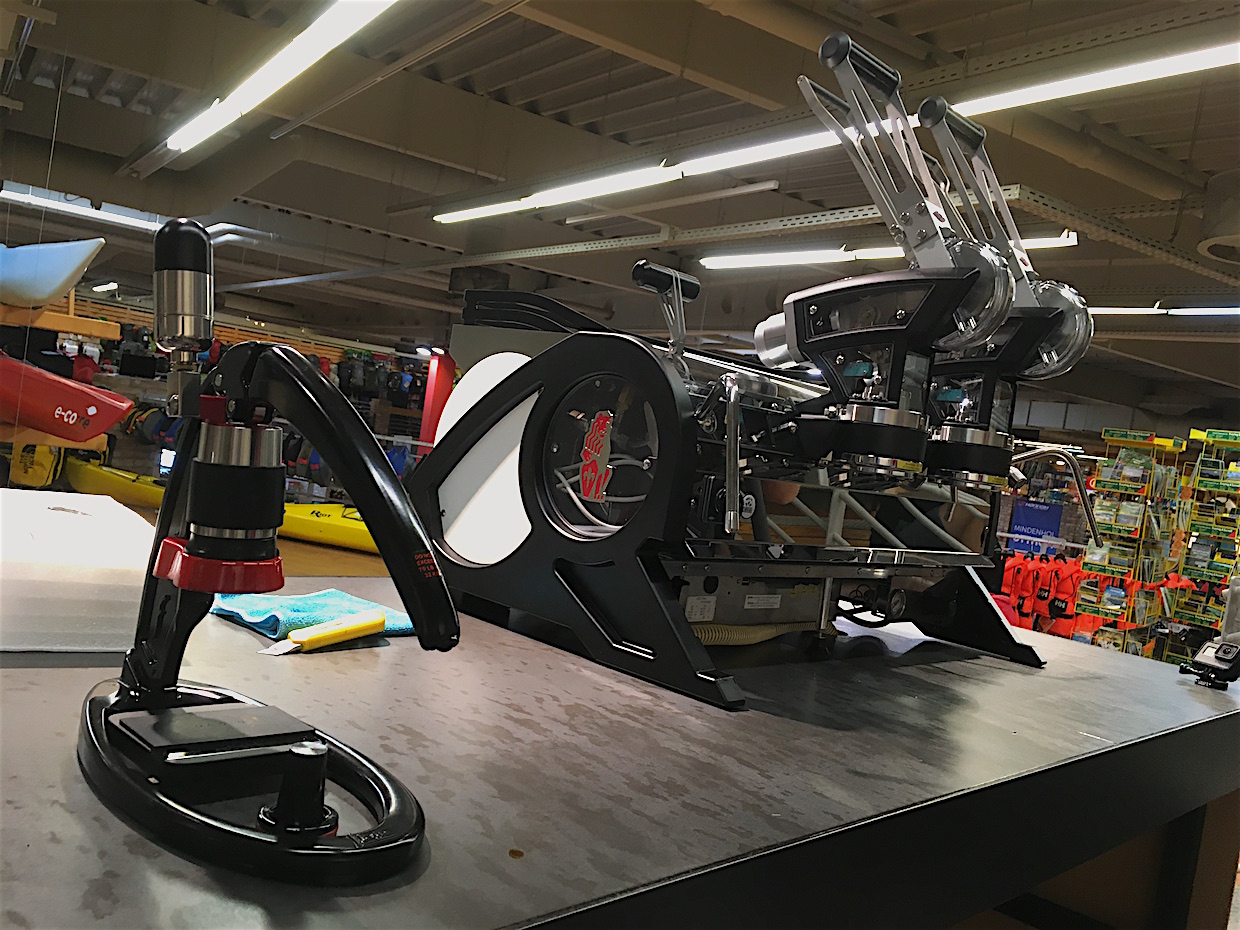

Vintage Faema Faemina manual lever espresso machine outfitted with the Smart Espresso Profiler. All photos care of Naked Portafilter.

Until recently, it has required thousands, if not tens of thousands of dollars’ worth of specialized equipment to accurately measure and act upon several of the more important factors in espresso brewing — factors such as the duration and force of pre-infusion, the pressure profile for the rest of the shot, and the cutting-edge tweak du jour: the flow rate.

These barriers to entry might be disintegrating, however, now that espresso accessory-maker Naked Portafilter has developed and launched a new tool for home and professional baristas that appears to be breaking the field wide open.

The Smart Espresso Profiler (SEP) is a Bluetooth-connected device that collects data from an increasingly wide spectrum of compatible groupheads, and coordinates with Acaia Lunar espresso scales to visualize a wealth of critical info on any connected device’s screen, thereby making new heights of espresso geekery available to exponentially more geeks.

The SEP, in conjunction with an Acaia Lunar, transmits information into an app that provides a real-time graphical display of an extraction’s time, pressure, weight, brew ratio and flow rate from start to finish. These shot profiles can be saved and shared, and even displayed in the background of subsequent shot charts in order to replicate a shot exactly or else tweak something at a precise moment.

“Our main goal with this development was to demonstrate the capability of levers, but as we could fit the hardware on various pump driven machines, it became a tool with a much wider reach,” said Gábor Laczkó, a professional tinkerer, filmmaker, Naked Portafilter founder and roaster for Hungary-based coffee company Kávékalmár.

“In coffee, today is everything about consistency,” Laczkó told DCN. “The more factors you have under your control, the easier [it will be] having consistency.”

One of the key breakthroughs of the SEP, according to Laczkó, is its visual confirmation and record of changes resulting from even the slightest adjustment to individual variables, assuming all others remain constant. Said Laczkó, “If you are consistent, and change only one parameter — dose, temp or grind for example — you will instantly see the effect on the flow/pressure profile and taste in your cup.”

The hardware carries a retail price of $410 and is compatible with any grouphead to which a pressure gauge can be attached, such as the La Marzocco GS3 MP, the Espresso Forge, and the E61 grouphead design adopted by such manufacturers as Rocket, Profitec, Lelit, Quickmill, Bezzera and others. The company has also designed special kits with precise custom replacement parts to which the device attaches. Kits are available for machines made by Olympia, La Pavoni, Streitman, the Flair, and even the popular pump-driven consumer Gaggia Classic.

If with minimal modification, the SEP can be fitted onto virtually any espresso machine, as Laczkó suggested, the door is theoretically open for mapping and recreating shots pulled on rare and obsolete machines, such as museum pieces and other antiques, either for enthusiasts’ curiosity or perhaps to create a Jurassic Park-like cafe, where prehistoric-style espresso is extracted anew to strike awe upon the palates of modern coffee drinkers.

“I could make a shot on my 65-year-old Faema Faemina and reproduce the same profile later on a Flair,” said Laczkó. “The possibilities are really unlimited.”

Surprisingly, the idea for the SEP actually wasn’t one birthed from within the intrepid Kávékalmár brain trust, although the bean didn’t fall far from the drum. It was a few months after displaying their original piston pressure kit at World of Coffee Budapest in June 2017 that Miklós Csanády, a regular consumer of Kávékalmár roasted coffees, pitched the idea of developing an application for pressure measurement and logging using a Bluetooth transducer instead of an analog gauge.

“At first I wasn’t very enthusiastic about that ‘mad’ idea, but he insisted,” said Laczkó. After further discussion they reached out to Acaia and found the scale-maker happy to support Lunar integration with the SEP project. With development furiously underway, and a few months remaining prior to the June 2018 World of Coffee Amsterdam goal the company set for launching a finished product, the maker of the Flair coincidentally inquired with Naked Portafilter regarding the possibility of developing an analog pressure gauge customization kit.

“The guys in the workshop next door presented the prototype [Flair] piston in record time, and we could feature the Flair with our application at the exhibition, too,” Laczkó said. “I can’t tell you enough how important a role [the workshop guys] have to make our ideas working.”

And so it came to pass that the Kávékalmár/Naked Portafilter booth at WOC Amsterdam gave the coffee world its first glimpse of one of today’s most minimal and mechanically simple electronics-free espresso makers performing some of the most complex espresso data extrapolation ever available.

“The exhibition was, for us, an extraordinary experience,” said Laczkó. “Plenty of the big guns — La Marzocco, Kees van der Westen, San Remo, Rancilio, Astoria, ECM, Conti, Lelit, etc. — visited our booth and came back later with their R&D teams. There is interest in further development for educational applications, even from cafe owners analyzing the shots and consistency in their shops. Our stand was under pressure for three days. One of the funniest moments was maybe that we could introduce Barb and Doug Garrott [of grinder-maker Orphan Espresso] to Kees van der Westen at our booth.”

This week, Laczkó reported yet another breakthrough for SEP compatibility and capability. The inventor just received approval from Decent Espresso CEO and Founder John Buckman to reveal that the two espresso-tech architects are working together on future data exchange between the SEP and the Decent Espresso system. The goal is to make SEP profiles visible and usable on Decent Espresso machines, and vice versa.

“Not only see, but a Decent owner could reproduce my 1953 Faema Faemina shot profile,” said Laczkó. “It will work also in the other direction. If John will share his favorite profile, I could put it in the background and reproduce it manually with a lever machine.”

A pressure- and PID-modified Gaggia Classic espresso machine additionally modified with the SEP system.

In the midst of all this, time has hardly stood still for the Kávékalmár roasting business. The company is now several weeks into construction of a new 2,100-square-foot production facility.

“We still roast on the 5-kilo Probat we featured in Roasted four years ago,” said Laczkó. “Our new one, a 12-kilo Probatone, is waiting for deployment.”

Speaking of the captivating intra-mechanical Roasted film series, Laczkó said a Part 3 is also in the works, as if he wasn’t keeping himself busy enough as it is.

“This [SEP] app will need to be cared for and developed further; there are already plenty of ideas from users,” Laczkó said of the path ahead. “Our new roastery is our next huge project, and hopefully I will find some time to finish Roasted III with Attila Zerczi before Christmas.”